Deep Cement Mixing Construction Method: DCM Construction Method

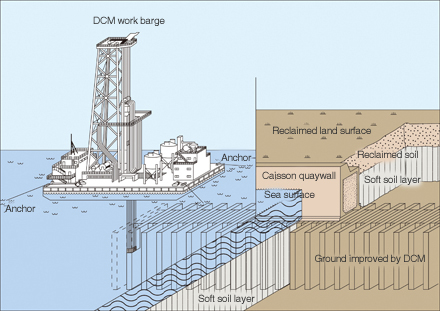

The DCM Construction Method is a construction method for improving soft ground by mixing a stabilizer (cement) with a soft soil layer formed by natural sedimentation or land reclamation at the position where the cement is to be used (in-situ placing) and allowing the mixture to solidify chemically. The Toyo DCM method is a systematized process, consisting of a series of technologies by which the stabilizer is produced in slurry form by the plant, conveyed to the mixing section at the leading end of the machine by a pressure pump, and achieves the specified uniform strength in the target range of the entire soil layer. It can be applied on both water and land.

Toyo Construction owns 3 ships dedicated to DCM Method, and has a long track record of DCM construction.

Features

- The specified improved strength can be obtained by changing the stabilizer addition rate corresponding to the soil quality of the target ground.

- Deformation of the improved ground due to loading is extremely small, and the effect on structures is minimal.

- DCM can be applied to improvement of all types of soft ground.

- Environment-friendly technology, as pollution of seawater and secondary pollution are minimal, and DCM is a low vibration, low noise method.

- No waste of resources, as soft soil from the construction site is used after processing.