SGM Lightweight Soil Construction Method

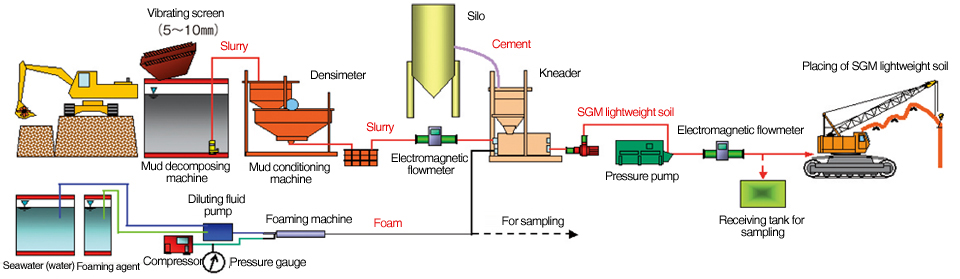

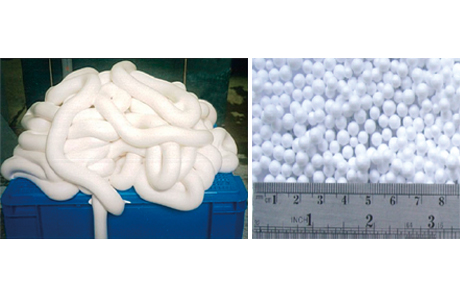

The SGM Lightweight Soil Construction Method is a construction method that creates stable ground which can withstand ground subsidence, earthquakes, and liquefaction. A civil engineering material (Super Geo-Material Lightweight Soil) which has adequate strength and is also light weight in comparison with general ground materials is produced by adding and mixing a stabilizer such as cement and a lightweight material such as foam, foam beads, etc. to dredged soil or surplus soil generated by construction. The system used in production of SGM lightweight soil enables adjustment to the optimum blend while continuously monitoring the amount of added stabilizer, the density of the treated soil, etc. so as to obtain stable strength and density at all times.

SGM lightweight soil is used widely in all parts of Japan, from the cold climate of Hokkaido to subtropical Okinawa. In particular, it has been adopted in many projects in urban areas like Tokyo, Osaka, Nagoya, Yokohama, etc.

Process from production to placing of SGM lightweight soil

Surface of SGM lightweight soil

Lightweight materials

Features

- Enables effective use of dredged soil and surplus construction soil with high water contents.

- Can realize compact bank sections and sheet pile wall sections.

- Comparatively minor tuning is possible, as required by structural changes such as seismic retrofitting, raising of seawall height, increased surcharge, increased depth, etc.

- Minimal effect on nearby structures such as existing embankments, structures, underground pipes, etc.