- TOYO HISTORY

- LANGUAGE

MODEC, Inc. (Chuo-ku, Tokyo, Yuji Kozai, President & Chief Executive Officer, hereinafter

“MODEC”), TOYO CONSTRUCTION CO., LTD. (Chiyoda-ku, Tokyo, Kyoji Takezawa,

Representative Director, President, hereinafter “Toyo Construction”), and Furukawa Electric Co., Ltd.

(Chiyoda-ku, Tokyo, Keiichi Kobayashi, Representative Director, President, hereinafter “Furukawa

Electric”) jointly applied for a publicly offered project “Research & study of technological

development for lowering construction cost of floating offshore wind power generation” related with

“Demonstration research of next-generation floating offshore wind power generation system

(Technological development for lowering construction cost of floating offshore wind power

generation)” by New Energy and Industrial Technology Development Organization (NEDO), and the

application has been adopted. We are delighted to announce that as of today, October 30, each of the

three companies entered into a business trust agreement with NEDO.

For realization of decarbonized society, offshore wind power generation, which has been introduced

mainly in Europe, is shifting its site location from at coastal area to more windy offshore area to raise

energy efficiency. Also, in Japan with large territorial sea, floating offshore wind power generation, in

addition to traditional bottom-mounted offshore wind power generation, is attracting attention.

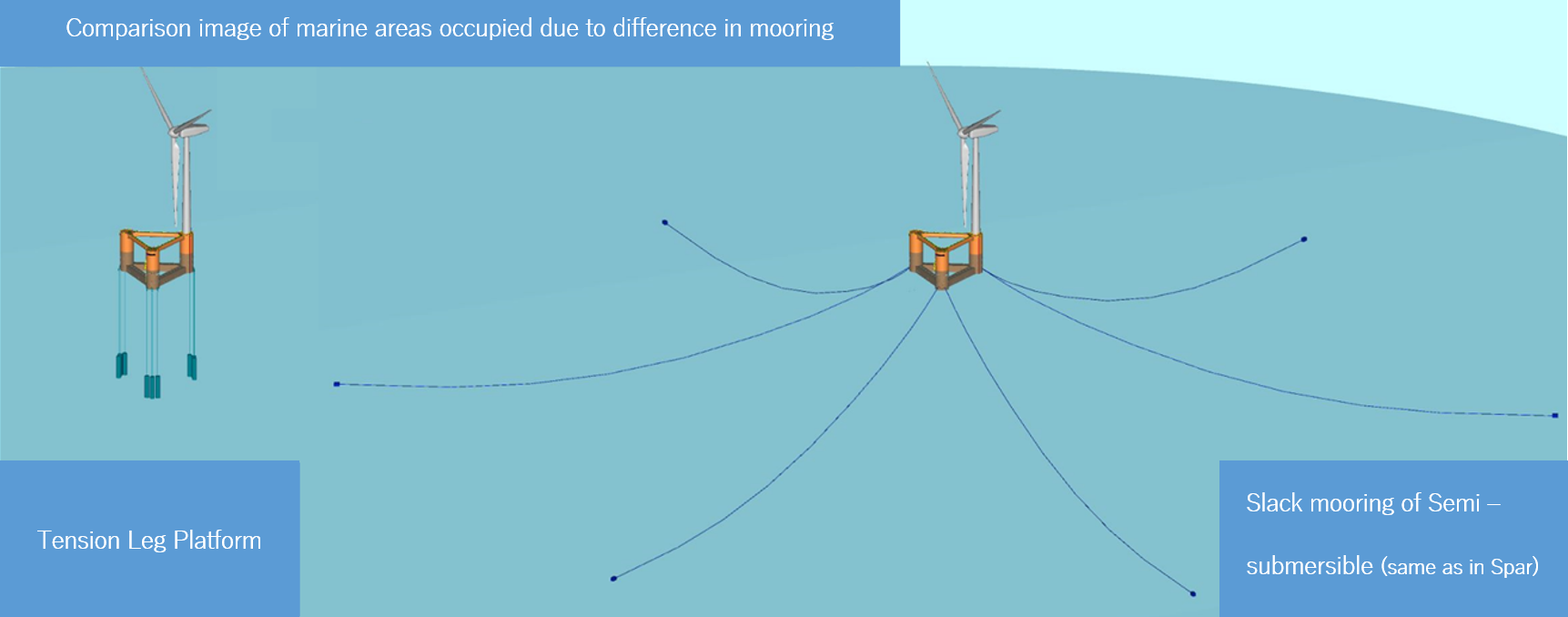

In this Research & Study, for mooring method of floating body, instead of a slack mooring method

which has been demonstrated domestically & abroad as a mooring method for floating body of

offshore wind power generation, a floating body mooring system by Tension Leg Platform (hereinafter

“TLP”) is adopted to reduce costs (see Figure 1 and 2). In the Research & Study, we will ensure

structure reliability required as a floating body mounting 10MW-over-class large windmill to be

assumed in real business operation by utilizing excellent dynamic response characteristic of floating

body on TLP, and also will develop low-cost next-generation floating body system and underwater

cable system by durability enhancement of wind power generation equipment and underwater power

transmission system due to little dynamic response. Also, compared with the slack mooring method,

it enables drastic reduction of space occupied in marine area by mooring line, therefore, it will

demonstrate excellent social receptivity by limiting influence on fishery and ship operation.

The term of this project is two years until March 2022. MODEC will be in charge of floating &

mooring system, Toyo Construction will be in charge of design of mooring foundation and offshore

works, and Furukawa Electric will be in charge of power transmission system, and then technology

development and cost reduction will be evaluated.

Toyo Construction is also working on demonstration experiment on technology of bottom-mounted

offshore wind power generation facility foundation (suction bucket foundation) with subsidy by

NEDO, and will establish construction method of offshore wind power generation facility foundation

for both of bottom-mounted and floating, and will contribute to the spread of offshore wind power

generation in the future in Japan.

[Figure 1] Image courtesy: MODEC, Inc.

[Figure 2] Image courtesy: MODEC, Inc.