Technologies and Solutions

Dam Conduit Drilling Method: Steel-Concrete Semicircular Cofferdam Construction Method

Conventional dam redevelopment construction methods, either the reservoir level is lowered sufficiently to allow work in a dry condition, or the reservoir level is lowered as much as possible and a temporary cofferdam for work with a low water depth (steel channel type anchor method, etc.) is installed. In both cases, this had a large effect on operation related to water use.

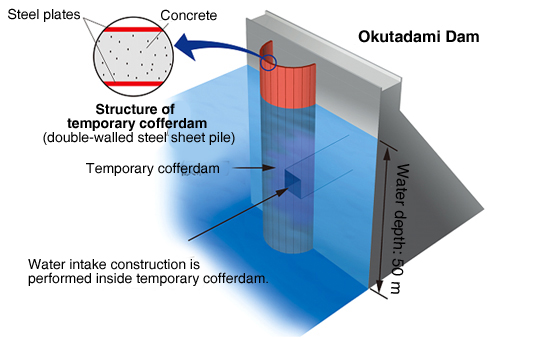

The Steel-Concrete Semicircular Cofferdam Construction Method was developed to make it possible to carry out dam-redevelopment projects without restrictions on water level. This cofferdam can withstand the high pressure at a maximum depth of 50 m, and thus enables dry work at large water depths.

Detail of cofferdam part

Features

- The “Steel-Concrete Semicircular Cofferdam Construction Method” can withstand the high water pressure at a maximum depth of 50 m, making it possible to perform dry construction work at large water depths.

- A continuous work space extending up to the water surface can be secured.

- As construction can be performed under a dry condition, it is possible to use general-purpose equipment, resulting in improved workability and economy.

- Because there are no restrictions on operation of the reservoir water level, dam redevelopment can be carried out while maintaining the water use function without change.

- As a method supporting effective utilization of the existing dam stock, this method is suitable for reservoir life extension by installation of sand removal equipment, flood control by installation of water discharge equipment, strengthening of water use functions, etc.