- TOYO HISTORY

- LANGUAGE

~ Investigate expressions and details thoroughly ~

By integrating the highly advanced CG technology into the BIM process, details of design contents can be precisely grasped during the period from the construction commencement to completion. By actively adopting innovative digital technology in the design and construction processes, material and texture of finishes after completion can be expressed photorealistically. Incorporating material data of products to be used in CG by highly advanced technology, the finished state can be expressed very precisely.

In addition, spatial recognition and confirmation of finishes using CG animation play highly significant roles as effective presentation contents and communication tools used between all people involved in a project including the client.

Representation technique in construction stage using BIM models

By precisely representing expressions of the completed state, speeding-up of the decision-making process and enhancement of customer satisfaction on a higher level are realized.

By using BIM models modeled for construction stage, precise signage plans can be studied.

By sharing BIM models with an elevator manufacturer at the construction BIM process stage, details and finishes can be studied at the construction stage.

Brightness after the completion can be accurately demonstrated by setting brightness levels based on light distribution data (IES).

Because brightness after the completion can be accurately demonstrated through lighting analysis considering daylight entering through openings, it is possible to conduct well-balanced and highly accurate lighting design studies.

Precise representation in full detail after completion

~ Simulation from design to operation ~

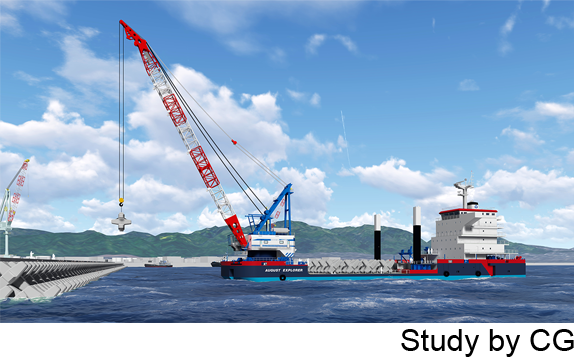

CG/BIM process is an effective visualization means in the design process of non-architectural fields. It is possible to speed up the consensus-building process between all people involved in the project, and also significantly shorten the time needed for decision making. Detailed modeling based on design drawings and accurate color expression (including hue, chroma, contrast, and reflection) work effectively in investigating visibility for safety assurance in the offshore work and also checking and verifying stylish forms and expressions.

Application examples of the BIM process to non-architectural fields

Color pattern simulation

AUGUST EXPLORER at the time of completion

3D printer

Model data are transmitted to the 3D printer to make models and die-casting metal molds.

Easy-to-understand explanatory documents

Realistic 3D models are effectively used as supplementary documents to explain operations after the ship goes into service.

Because various marine operations including port development involve operations under severe natural conditions, thorough explanations using easy-to-understand documents are needed.

Images of operation

AUGUST EXPLORER specifications

Ship body size: total length 89.9 m, width 27 m, depth 5 m

Maximum lifting capacity: 500 t

Maximum load capacity: 3,500 t

Maximum passenger capacity: 52

Gross tonnage: 4,831 t

Maximum service speed: approximately12 knot

DPS: tide 2 knot + wind velocity 15 m

(responding to all directions)

Propulsion device: full-circle slewing type, 1,417 kW×2 units

Bow thruster: elevating and full-circle slewing type, 590 kW×2 units

Supplementary thruster: tunnel type, 330 kW×1 unit

Navigation area: greater coasting area (non-international)