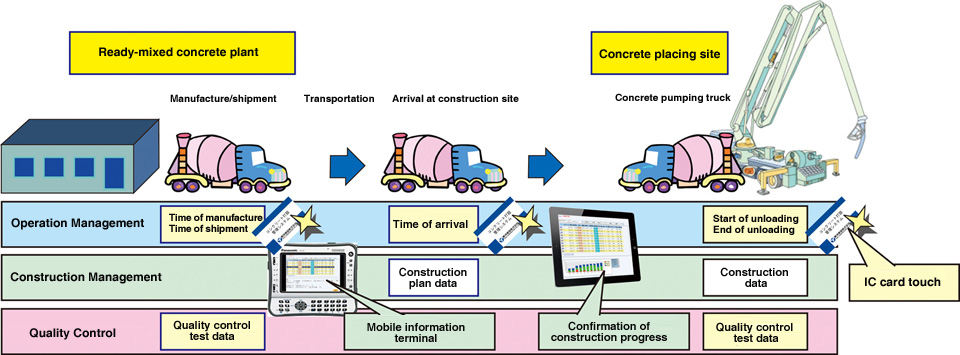

Concrete Placing Management System

In the Concrete Placing Management System, placing of ready-mixed concrete is managed by using the internet and IC cards (RFID). Information including the status of operation of concrete mixer trucks, average transportation time, the time interval for placing on consolidated fresh concrete, results of quality control tests, and the allowable time until completion of placing for each concrete mixing truck is grasped in real time by personal computers and RFID card readers installed at the ready-mixed concrete plant and the concrete placing site, and the system is shared by the concrete manufacturer and the construction manager.

By grasping the time of manufacture and the transportation/waiting status of ready-mixed concrete, this system makes it possible to avoid traffic congestion and decreased concrete quality due to back-up of mixer trucks during the period until placing is complete, and to prevent cold joints and other defects by control of the time for placing on consolidated concrete.

Flow of System

Example of application site (1)

Example of application site (2)

Features

- The ready-mixed concrete manufacture time, shipment time, and unloading start/end times are registered in a server database when the IC card (RFID) carried by the driver of the concrete mixing truck touches the card readers at the manufacturing plant and the construction site office, making it possible to grasp the status of shipment, transportation, truck backups at the site, etc. in real time.

- Using a mobile terminal, the person in charge of the nozzle registers the time of the start and end of concrete placing at the concrete-placing location, which is divided into blocks in the construction plan. The status of operation of concrete trucks and the results of tests at the site are checked by the system. Sure concrete placing in accordance with the construction plan is possible by giving appropriate instructions to the shipping plant and concrete pumping truck based on the condition of placing. It is also possible to check the progress of construction by comparing the actual results of concrete placing, which are input in real time, with the placing sequence and quantity data that were input in advance.

- Registration of the results of quality control tests at the concrete manufacturing plant and the construction site enables real-time sharing of quality control data, including transportation and construction work information, and quick feedback to the manufacturing process. As a result, high quality concrete structures and supply are possible.