Mechanical Dewatering Method: CYPRESS Method

With conventional mechanical dewatering methods, the discharged dewatered cake was treated as waste. With the CYPRESS method, it is possible to dewater mud efficiently by a newly-developed pressing mechanism and obtain strength that satisfies the standard for reuse, enabling recycling of dredged bottom mud and surplus soil generated by construction.

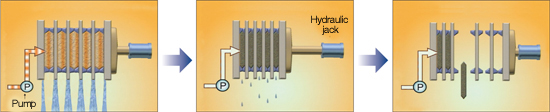

In the primary dewatering process in the CYPRESS method, slurry is driven into a closed filtration chamber by a pump, and the filtered water is discharged out the system via the filter cloth.

In the second part of the primary dewatering process, the filtered water flow rate decreases and dewatering efficiency is reduced. Therefore, high efficiency dewatering is performed in a short time by secondary pressing using a hydraulic jack.

After this process, the hydraulic jack is retracted, and the dewatered cake is successively discharged. The cake strength satisfies the reuse standard for surplus soil generated by construction.

Features

- A newly-developed pressing mechanism enables volume reduction and increased strength with hard-to-dewater mud when treating a high water content and contains organic matter.

- In comparison with the conventional filter press, the same or higher strength development can be obtained in about half the time; as a result, construction efficiency is greatly improved.

- At the same dewatering time, strength (cone index) is more than two times higher than with the conventional filter press. Because the product dewatered cake satisfies the standard for reuse of surplus soil generated by construction, recycling is possible.