Technologies and Solutions

Mechanical Rubble Leveling Construction Method

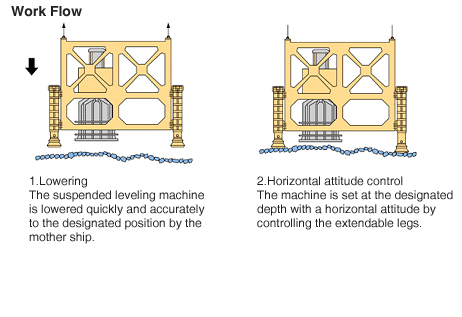

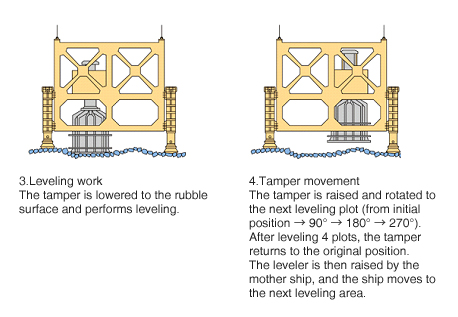

The Mechanical Rubble Leveling Construction Method enables extremely accurate (±5cm), large volume, high speed leveling in deep water (to –40m) for the rubble mounds used as foundations for breakwaters and seawalls. The leveling machine is seated on the rubble on the sea bottom by four legs, and the mound surface is leveled by a tamper installed in the vibration generator, realizing speedy completion of compacting work.

This Toyo Construction technology already has an extensive record of use in breakwater and seawall rubble leveling work in projects throughout Japan.

Features

- Leveling is possible in water depths to –40m.

- Fast, large volume work is possible, as the standard leveling area is 200m2/day.

- Because leveling is performed by vertical vibration of the tamper, which is housed in the vibration generator, a strong and flat rubble mound can be formed.

- As this is a wave buffering device, work is not affected by pitching and rolling of the ship in waves. Furthermore, because all measured data are collected and remote operation is performed from a dedicated mother ship, extremely accurate work control is possible.

- Since leveling work is performed by remote operation on the mother ship, it is not necessary for divers to work under high pressure conditions. As a result, safety is dramatically improved.