- TOYO HISTORY

- LANGUAGE

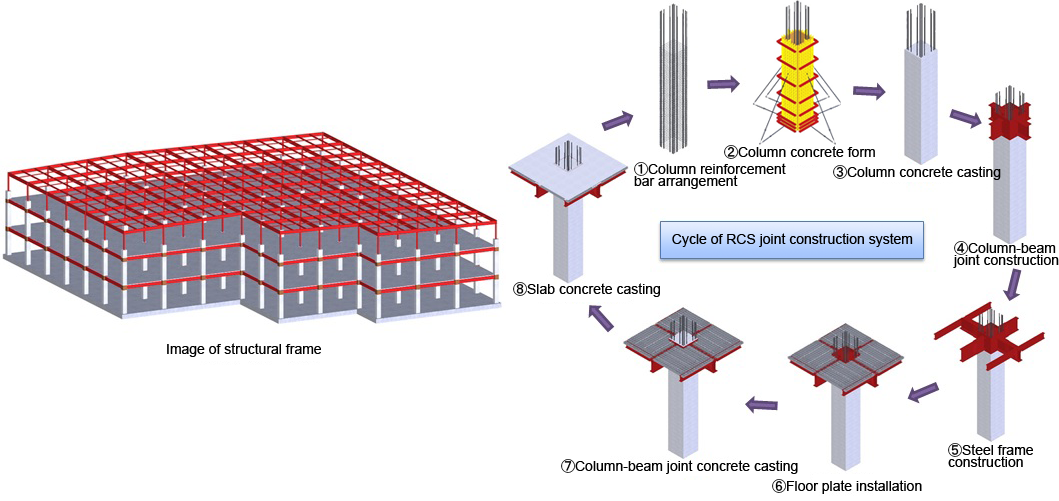

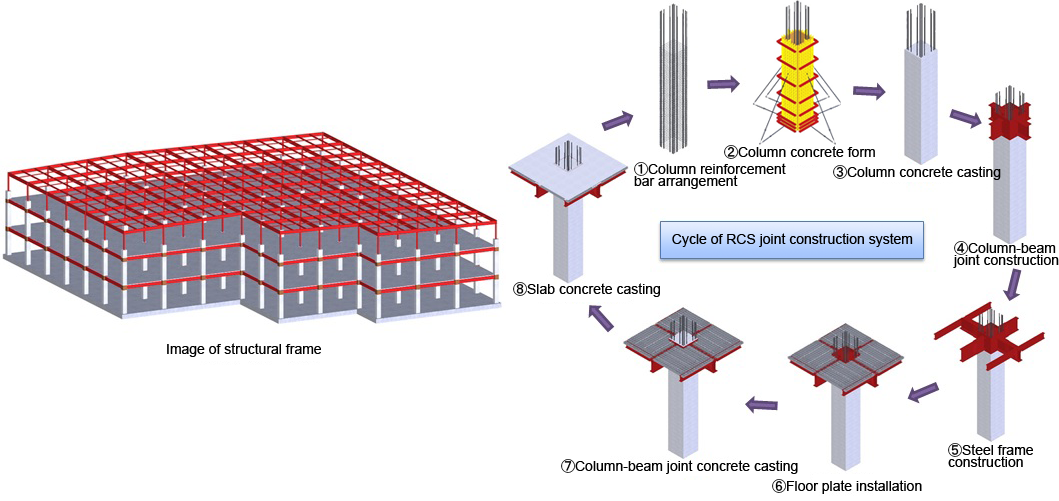

This structural system is composed of reinforced concrete columns with high compressive strength connected with steel structure beams with light weight and high tensile strength, and capable of realizing longer spans than the reinforced concrete structure. It is a hybrid structural system with advantages of both the reinforced concrete structure and steel structure and suitable for logistics facilities, production facilities, and commercial facilities.

This construction method is a structural system developed through joint efforts by three companies including Maeda Corporation, Zenitaka Corporation, and Toyo Construction, and it has obtained the Performance Evaluation Certificate from the General Building Research Corporation of Japan (issue number 08-13 rev.3 (19 May, 2015)).

Features

- Since the spans between columns can be long due to the steel beams capable of carrying long spans, it is suitable for buildings with large spaces such as logistics facilities, production facilities and commercial facilities.

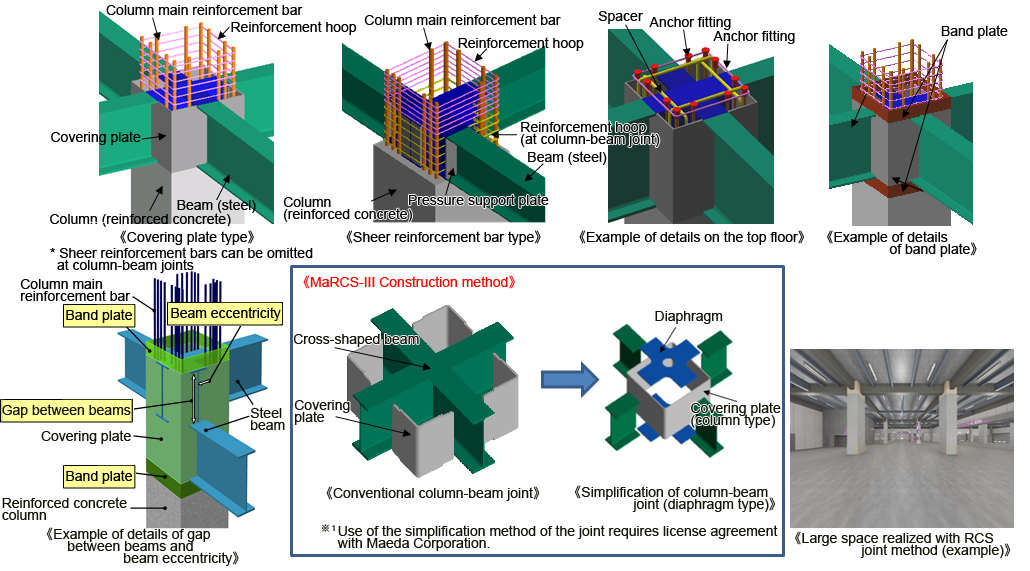

- There are two types for the column-beam joint, namely the “covering plate type”, which covers the joint with steel plate with excellent workability, and the “sheer reinforcement type”, which does not expose the steel plate on the building perimeter.

- Maximum load for concrete in columns is FC=60 N/mm2 (joint: 48 N/mm2) and steel bars with high-strength material (SD490) can be used as main reinforcement in columns, and it is also suitable for buildings with large superimposed load.

- Structural strength of joints can be increased by installing band plates above and below the joints, and thus the section of joints can be reduced.

- Since it is capable of setting level differences between floor beams and making eccentric beams, the building can be designed tailored to customers’ needs.

- According to the conventional construction method, large beams are assembled in cross-shape and covering plates are divided in four and attached to the beams. In the new method, steel fabrication of parts at column-beam joints can be simplified by attaching diaphragms to the top and bottom of covering plates and large beams are connected to the diaphragms.※1

Construction examples

- ●Logi Square Kasukabe (logistics warehouse)