- TOYO HISTORY

- LANGUAGE

TOYO CONSTRUCTION CO.,LTD. (Chiyoda-ku, Tokyo, Kyoji Takezawa, Representative Director, President: hereinafter referred to as “Toyo Construction”) and Hitachi Zosen Corporation (Osaka City, Osaka, Takashi Tanisho, Representative Director Chairman & President: hereinafter referred to as “Hitachi Zosen”) will commence verification of construction technology of suction bucket foundation, which will lower costs of bottom-mounted offshore wind power generation facilities (lowering capital cost by 20%).

This project will be implemented with subsidy by NEDO (New Energy and Industrial Technology Development Organization) for “Low-Cost Construction Technology Development for Offshore Wind Power Generation (Verification of Construction Technology)” of Research and Development of Wind Power Generation Technologies (Research and Development of Offshore Wind Power Generation Technologies).

Suction bucket foundation is a construction method proven in Europe as a foundation for offshore wind power generation facilities, and also domestically has been applied for breakwaters. This verification is undertaken not only to verify applicability of suction bucket foundation to domestic offshore wind power generation facilities which are under different conditions in Europe, but also to develop technologies including basic form & construction technology to meet windmills growing in size in order to prepare for widespread construction of windmills with 10MW or more in capacity.

The main contents of the verification are as following:

① FY 2019 and 2020

To conduct soil tank test using suction bucket foundation of approximately 1/10 scale model at Technical Research Institute of Toyo Construction in Naruo (Nishinomiya City, Hyogo pref.), and also confirm structural & ground behavior and sinking & removal workability. To conduct centrifugal field test at Disaster Prevention Research Institute of Kyoto University (Uji City, Kyoto pref.), and based on the numerical analysis results of both tests, to commence consideration of experiment in actual marine area scheduled in the next fiscal year and design & fabrication of suction bucket foundation to be used for the experiment.

② FY 2021

To conduct penetration & pull-out test and evaluate structural & ground interaction behavior.

③ FY 2022

To conduct verification of preparation status for large windmills and obtain a technical certification from a public institution.

The primary advantages of suction bucket foundation are as following:

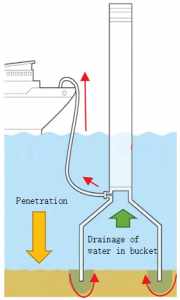

① No need for large construction equipment – penetration into ground by pump drainage

② Enabling complete removal by using same equipment for installation – by filling water in a procedure opposite to penetration

③ No big noise or vibration during penetration & removal work

The two companies will contribute to the realization of a low carbon & sound material-cycle society by developing technologies for spread of clean energy.

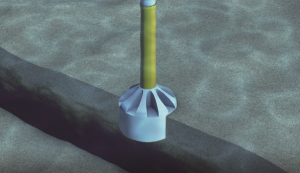

Application example for large windmill

Mechanism of suction bucket

Cross-section of suction bucket installation