- TOYO HISTORY

- LANGUAGE

Tokyo – 21 January 2022 – Toyo Construction Co., Ltd. (“Toyo Construction”), together with

MODEC, Inc. (“MODEC”), Furukawa Electric Industry Co., Ltd. (“Furukawa Electric”), and

JERA Co., Inc. (“JERA”), has received, on 21 January, notice of acceptance of their joint

grant application, under the Green Innovation Fund program of the New Energy and

Industrial Technology Development Organization (“NEDO”), to conduct a project to

develop cost-reducing technology for tension leg platform (“TLP”) floating offshore wind

turbines (the “Project”).

To achieve carbon neutrality by 2050, the Japanese government has set a goal of increasing

offshore wind power generation capacity, including floating offshore wind, to 30–45 GW by 2040.

Because Japan has limited shallow-water sites where the bottom-fixed offshore wind turbines

now being developed around the world can be installed, there is a strong domestic demand for

practical floating offshore wind turbines that can be installed in deep water further from shore.

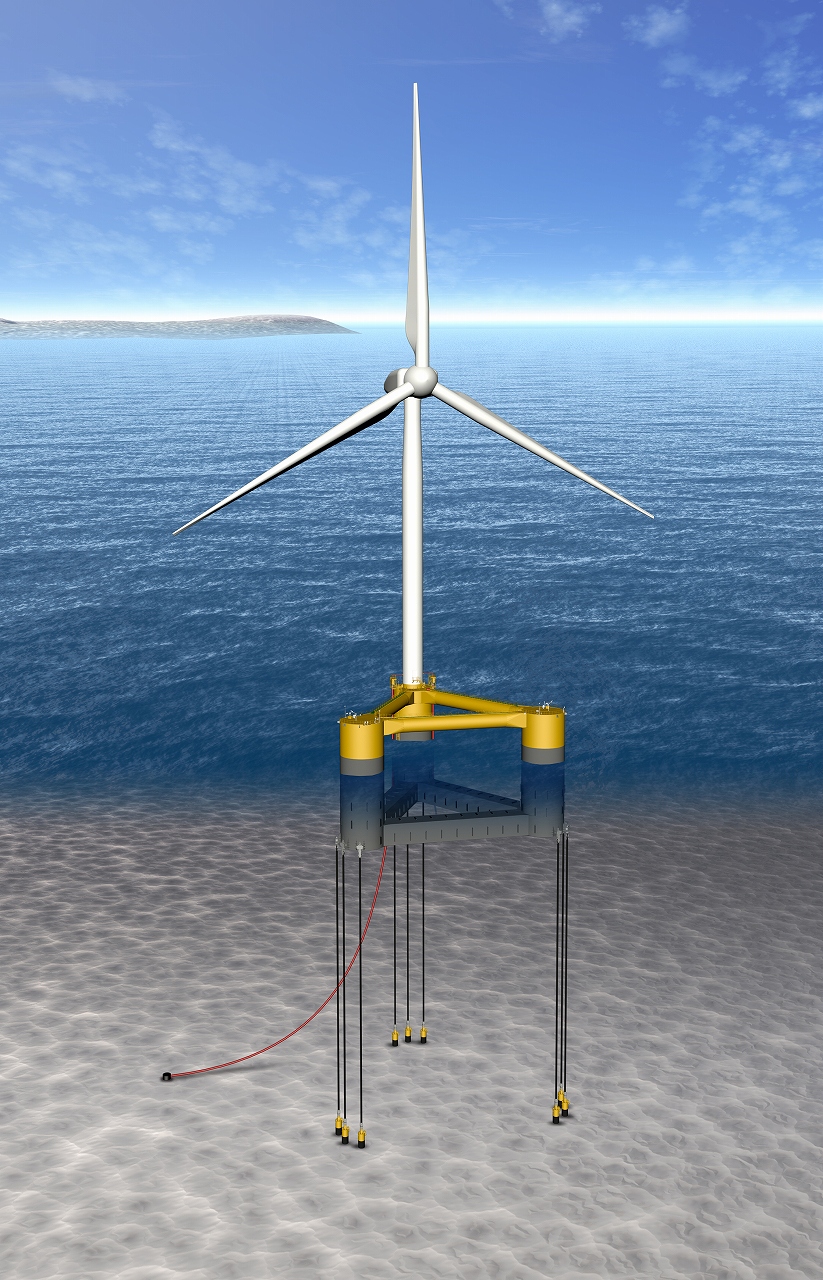

TLP systems are expected to reduce the cost of power generation because the high stability

of tension mooring to a seafloor foundation enables installation of large 15 MW-class wind turbines,

which have the potential to become mainstream in the future, on compact floating platforms.

In addition, TLP mooring lines are expected to be more socially acceptable than other mooring systems

because they can reduce the space occupied under the sea by 1/1,000 approximately and have less

impact on existing businesses such as the fishing industry and ship operations.

The Project aims to establish component technologies for TLP floating and mooring systems

and subsea power transmission systems with the aim of commercializing floating wind farms

in the early 2030s.

The four companies will jointly conduct component technology development under contract from NEDO

for two years beginning in April 2022. JERA will conduct surveys and measurement of the planned

verification site, design power generation facilities, and establish environmental parameters.

In addition to conducting simulations and demonstrations of component technologies previously studied

by each company—floating and mooring systems by MODEC, mooring foundations by Toyo Construction,

and power transmission systems by Furukawa Electric—a basic plan for a 15 MW-class power generation

demonstration facility will be drawn up based on design and environmental parameters provided by JERA.

The four companies will also begin considering supply chains for mass production and cost reduction

with the aim of realizing commercial projects following the power generation demonstration.

Toyo Construction raises the offshore-wind-power related business as a “growth driver” and

is promoting the business to make it our future core business. Particularly, we put priority and

focus on developing technologies for lowering costs related to the offshore wind power generation

business. In this business, we will contribute to the spread of offshore wind power generation in the

future in Japan with maximized utilization of our rich track record in the design and construction of

offshore structure.

Conceptual drawing of TLP (Tension Leg Platform)[Source: MODEC]