- TOYO HISTORY

- LANGUAGE

The CELBIC Study Group (consisting of thirteen companies: Haseko Corporation (organizer), Asunaro Aoki

Construction Co., Ltd., Asanuma Corporation, Hazama Ando Corporation, Okumura Corporation, Kumagai Gumi

Co., Ltd., Konoike Construction Co., Ltd., Penta-Ocean Construction Co., Ltd., The Zenitaka Corporation, Tekken

Corporation, Tokyu Construction Co., Ltd., Toyo Construction Co., Ltd, and Yahagi Construction Co., Ltd.) has

obtained a Certificate of Technical Performance for Construction Materials (GBRC Material Certification No. 20-

02) from General Building Research Corporation of Japan as of October 5, 2020 for “Environmentally Friendly

BF Concrete (CELBIC)”, a concrete made of ordinary Portland cement mixed with 10-70% ground granulated

blast-furnace slag.

CELBIC, an acronym for “Consideration for Environmental Load using Blast Furnace Slag In Concrete”, is an

environmentally friendly concrete that reduces carbon dioxide emissions from concrete materials by approximately 9 to

63% while ensuring the quality of concrete required for construction of concrete structures, aiming to contribute to

establishing a sound material-cycle society and solving global environmental issues. CELBIC can be manufactured and

shipped as a concrete conforming to JIS A 5308 (ready-mixed concrete) and will be constructed under the responsibility

of the thirteen companies participating in the CELBIC Study Group.

In the future, we will apply this environmentally friendly CELBIC effectively and efficiently to buildings and other

reinforced concrete structures in order to encourage the widespread use.

Certificate of Technical Performance for Construction Materials for CELBIC

Mock-up specimen fabricated in the development experiment

■Environmental considerations

Ground granulated blast-furnace slag is made by pulverizing by-product slag produced during pig iron making in the

blast furnaces of ironworks and has hydraulic properties.

Since the amount of carbon dioxide emitted during the manufacture of ground granulated blast-furnace slag is less

than 1/20 than that of ordinary Portland cement, effective use of this granules is desired to reduce the environmental

impact.

Ground granulated blast-furnace slag is a concrete material used as a substitute for cement as one of the admixture

materials under JIS A 5308 (ready-mixed concrete). In general, it is distributed as blast furnace slag cement class B,

which is pre-mixed with Portland cement in a prescribed amount (at 40-45%) at a cement plant.

■Features

CELBIC is produced in a ready-mixed concrete plant using ordinary Portland cement and ground granulated blast-

furnace slag as the concrete material, and according to the application parts or components of the building and the

specified performance, 10% to 70% of the cement is replaced with ground granulated blast-furnace slag.

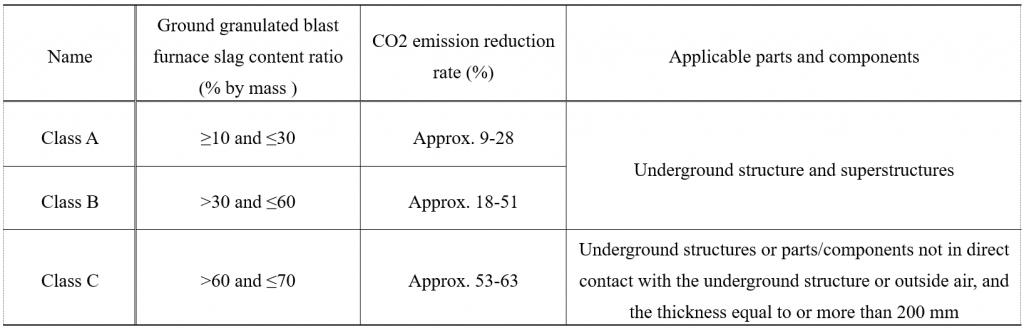

CELBIC is classified into three classes according to the amount of ground granulated blast-furnace slag: Class A,

Class B and Class C.

Of these, Class A has performance similar to concrete made of ordinary Portland cement, while Class B has

performance similar to that of blast furnace slag cement Class B. Class C reduces carbon dioxide emissions by more

than 60%, although the application at sites are limited. In addition, since these three types of CELBICs use the same

ground granulated blast-furnace slag, the burden of material management at the ready-mixed concrete plants is

alleviated, and generic application for building structures by taking advantage of the distinctive features of each type

is expected.

Names of CELBIC types, ground granulated blast furnace slag content ratio, Co2 reduction rate, and applicable parts and components

■Development experiment

In the development experiment, we confirmed the strength development and durability of concrete under various

conditions using several kinds of ground granulated blast furnace slag mainly distributed in Japan, and verified the

basic performance of the concrete according to the content ratio of ground granulated blast-furnace slag.

Based on the results, we determined the selection of the plant and the method of concrete mix design, followed by

the construction verification assuming the manufacture of CELBIC and actual parts and components at the actual

ready-mixed concrete plant, and prepared the mix design & construction manual for CELBIC.